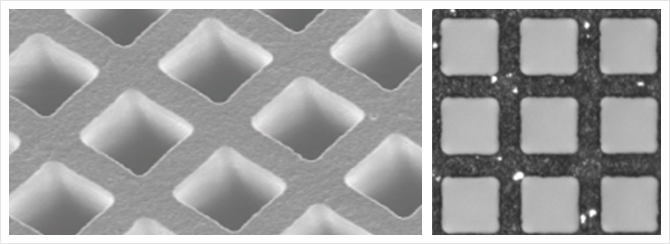

Laser Micro Hole Drilling SDL-FI200

OUTLINE

- Vertical Probe card guide plate hole processing

- Hole processing according to Flexible probe pin shape

- Various types of material

(Ceramic, Polymers, Metal, Glass, etc.)

FEATURES

- High precision universal laser system (IR Pulsed Laser)

- High precision Scan System (Scan System Auto Calibration S/W)

- X,Y,Z,T Linear Motion System (2D Motion Auto Calibration S/W)

- Integrated Auto inspection Vision System

- Maximum hole processing size : 200mm × 200mm

- On The Fly Option

SPEC

| Si3N4 (Silicon Nitride) | 0.125 T | 0.25 T |

|---|---|---|

| Min. Hole Size | 30 × 30um | 30 × 30um |

| Min. Hole Pitch | > 40um | > 50um |

| Hole Taper | < 5um | < 10um |

| Corner Radius of Rectangular Hole | < R 4um | < R 6um |

| Hole Size Repeatability | ± 1.5um | ± 1.5um |

| Hole Position Error | ± 1.5um | ± 1.5um |

Micro Rectangular Holes on Guide Plates

Low Leakage Tester

OUTLINE

- Probe card reliability verification equipment for DC parameter testing process

- To determine the interference between the channels of the probe card, measure the leakage current for each channel

SPEC

| ITEM | SPEC |

|---|---|

| Measuring Instruments | Keithley 6430 |

| Communication | RS232 |

| Number of Channel | 48CH. (Max : ~128CH) |

| Channel Board | 8CH. Per 1board |

| Measurement Range | 10aA ~ 105mA |

| Source Voltage | 0V~20V |

| Operating Environment | Temperature : 20℃(±1℃) Humidity : 30%~50% |

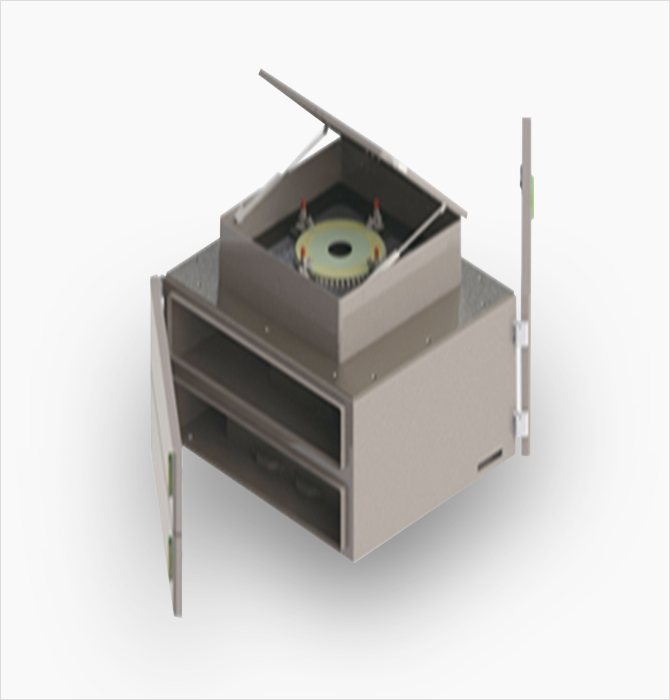

Relay Switching Board for Probe Card Tester

OUTLINE

- Probe Card Electrical Characterization Testing Equipment

- Replacement of mechanical relay channel control with electronic switch (MAX313L, Analog Switch)

- Guaranteed relay permanent lifespan, equipment miniaturization, and improved measurement speed

SPEC

| ITEM | SPEC |

|---|---|

| Measuring Instruments | Keithley 6487 Source Meter Agilent 4263B LCR Meter |

| Communication | RS485 |

| Number of Channel | ~ 5400CH |

| Channel Board | 100CH. per 1board |

| Source Voltage | 0V~20V |

| Operating Environment | Temperature : 20℃(±1℃) Humidity : 30%~50% |

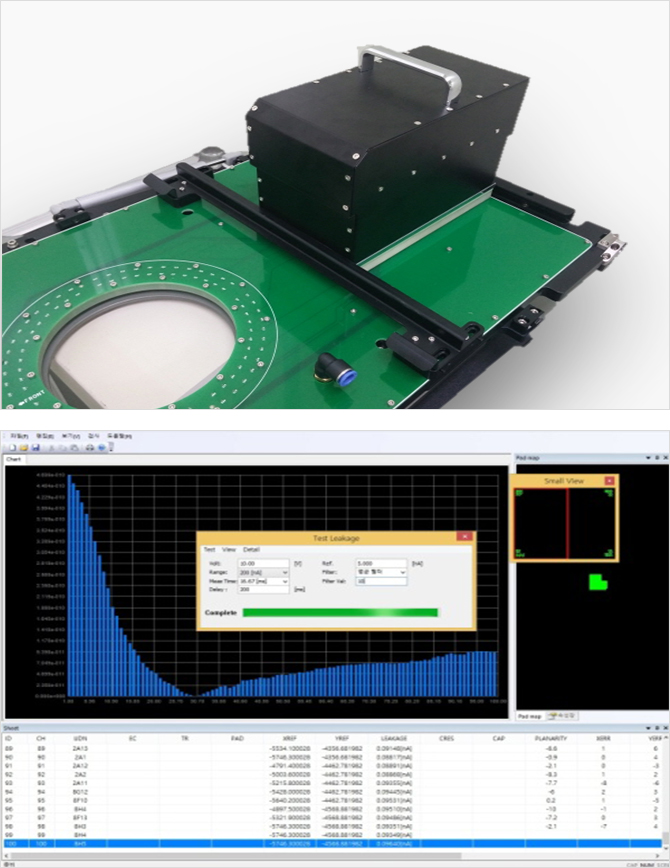

Probe Card Tester SDP3000

OUTLINE

- Probe Card Electrical Characterization Testing Equipment

- Capability to verify the X & Y positions and diameter of probe card tips

- Ability to test open and contact resistance of probe card tips

SPEC

| Item | SPEC | |

|---|---|---|

| Probe stage | x, y working area | 200X200mm |

| z axis working area: | 12mm | |

| z axis force | >100kg | |

| x, y, z precision | ±1um | |

| repeatability | ±1um | |

| Vision | F.O.V | X=0.86mm(SCAN) |

| working Distance | 20mm±2mm | |

| CCD | ½” | |

| resolution | 1600X1200 pixel | |

| Leakage Test | 1pA~2mA | |

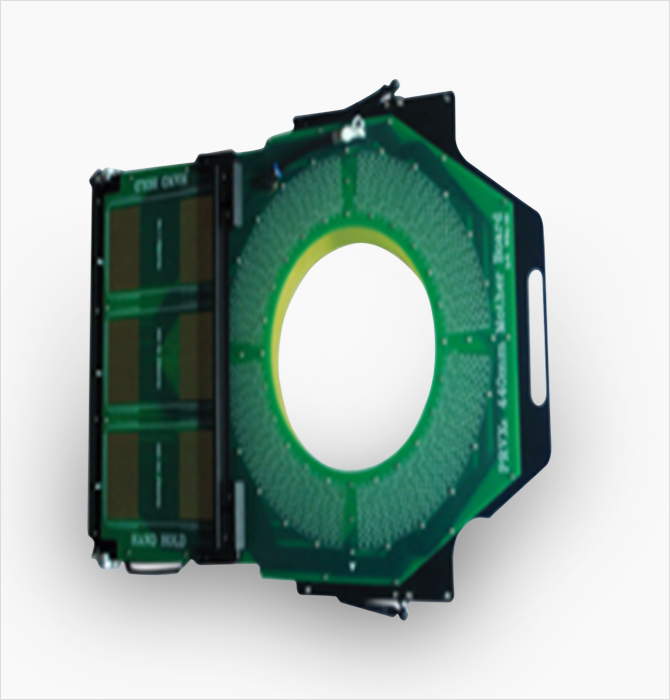

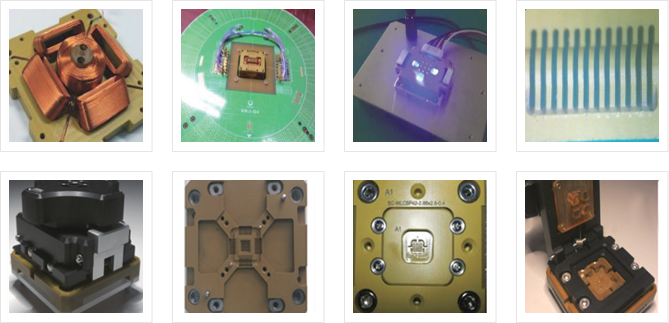

PRVX Mother Board

OUTLINE

- Motherboard used with probe card analysis equipment

- Components required for probe card correlation and performance measurement before production wafer testing

SPEC

| Layer | SPEC |

|---|---|

| Test Device | BGA, WLCSP, LED, ETC |

| Test Pitch (mm) | 0.35 / 0.4 / 0.5 / 0.65 / 0.75 / 0.8 / 1.0 |

| Temp | -50℃ ~ 200℃ |

| Life Cycles | > 300,000 Cycles |

| Test Pin | POGO Pin, J contactor |

Probe Card Manual Tester SDP-200C

OUTLINE

- Manual inspection equipment for checking the connection between the probe pin and main PCB during the probe card manufacturing process

- Process equipment used to check the connection status of probe pins after probe card assembly or before shipment

SPEC

| ITEM | Contents |

|---|---|

| PC Specification | - CPU: Pentium

- OS: Windows 7 or higher - Monitor: 17” or larger - RAM: 2GB or more - Communication: RS232 |

| Equipment Size | 500mm × 1000mm × 550mm (excluding PC) |

| Equipment Weight | 30kg |

| Power | AC220V (60hz) |

| Current Consumption | 300mA or less |

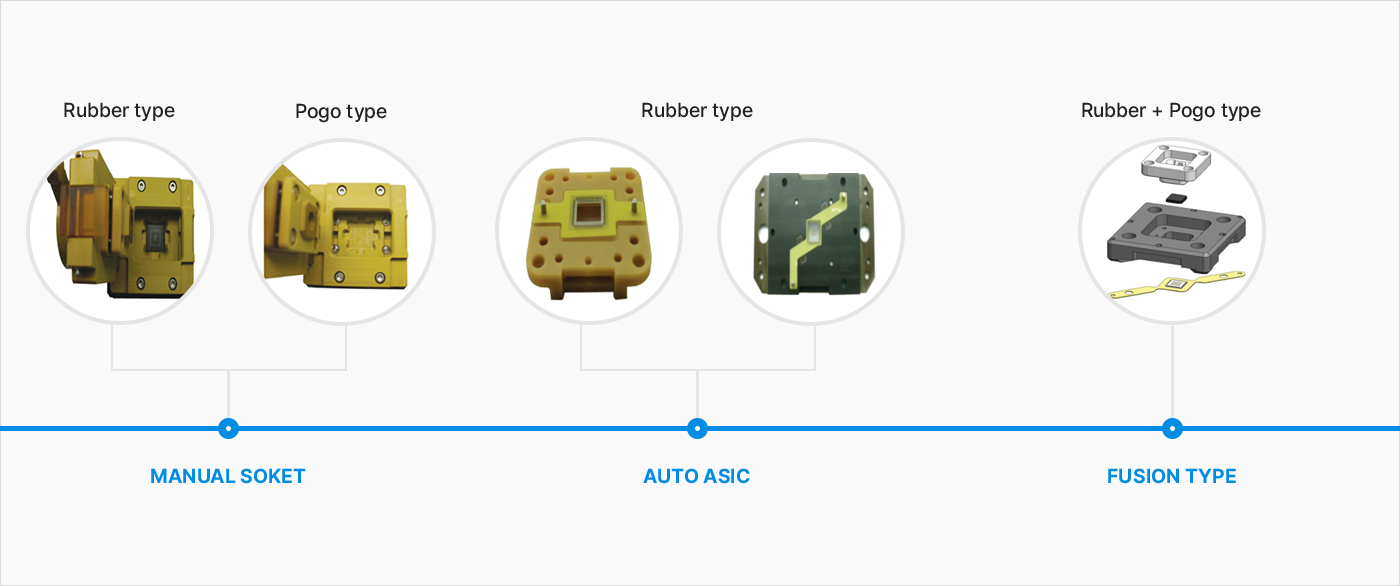

Capability to manufacture various sockets for package verification

| ITEM | SPEC |

|---|---|

| Test device | BGA, WLCSP, LED, ETC |

| Test pitch[mm] | 0.35/0.4/0.5/0.65/0.75/0.8/1.0 |

| Temperature | -50℃ ~ 200℃ |

| Life cycle | > 300,000 Cycles |

| Test pin | POGO Pin, J contactor |

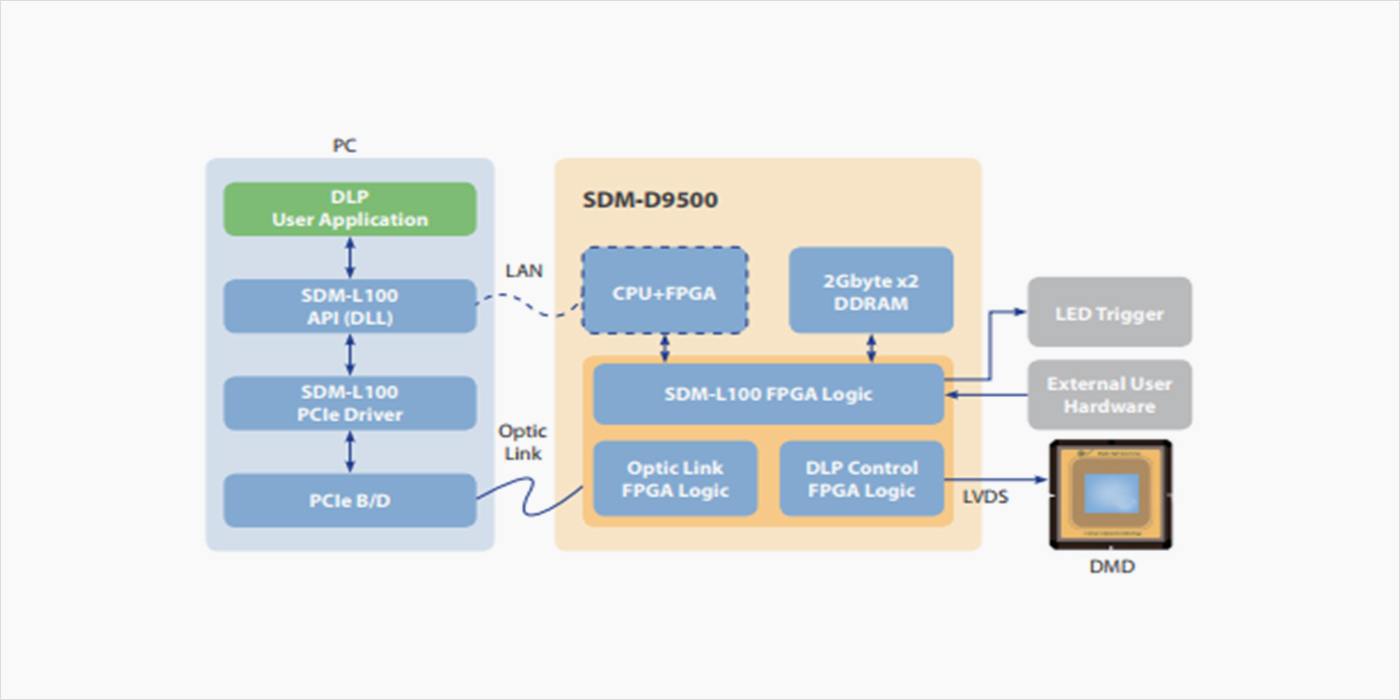

DMD Controller for Direct Image Exposer

OUTLINE

- Controller for DLP 9500 Chip control

- Equipped with high-precision micro-pattern exposure algorithms

- Capable of development and production in OEM format

- Provides a rich software library optimized for image processing and exposure

SPEC

| ITEM | Common DMD Controller |

SDM-D9500 |

|---|---|---|

| DMD Tilting Angle | Fixed | Flexible |

| Exposer Resolution | Fixed | Flexible |

| Image Processing | S/W &H/W | S/W |

| FPGA Logic | H/W Dependent | H/W Independent |

FEATURE

-

Exposure method

-Application of DMD rotation and parallel exposure algorithms

- Various DMD tilt angles can be applied based on environment settings via software

-

Frame Per Sec

- 1920x1080 HD Binary Image at 16,000 FPS

- 1024x768 XGA Binary Image at 22,000 FPS

-

Brightness control

- Light intensity control via software

-

Image Format

- DXF File

- Gerber File

-

Main Feature

- No need for high-speed communication processing, reducing the controller size and hardware cost

- Adoption of an open hardware architecture, enabling the application of various applications

-

Power

- DC 12V, 8A

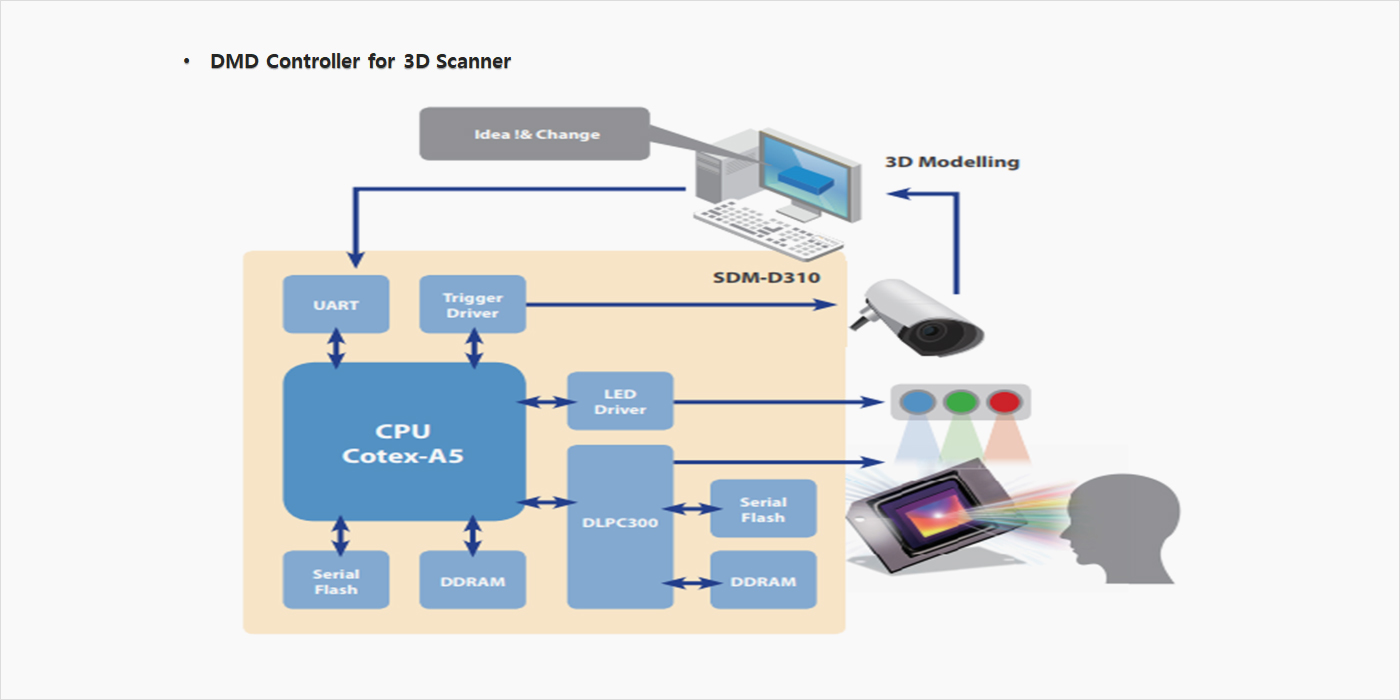

DMD Controller for Direct Image Exposer

OUTLINE

- DMD Controller for compact 3D scanners

- Custom-made to optimize for the customer's system, with a provided software library

- Produced and supplied in OEM format

- Designed with only firmware and FPGA, ensuring hardware stability without using an OS kernel

FEATURE

-

Resolution

- 608 x 684

-

Frame Per Sec

- 360, 720, 960, 1440Hz (Max.4000Hz) @1bit

-

Number of patterns

- 20 Pattens

-

Image Format

- bitmap format

-

Interface

- UART

-

Electrical Characteristics

- Power Supply : DC 5V, 2A

- Operating Temperature : -20°C ~ 85°C

- Storage Temperature : -40°C ~ 85°C

- RGB LED Current : Min 300mA, Max 1.5A