Direct Imaging System SDES Series

OUTLINE

- Process for all layer including inner, outer and Solder mask.

- Optimized for small quantities of many varieties.

- Prompt sample production lead-time

- Mass production for high density HDI

FEATURE

- High precision double-sided exposure technology.

- High intensity Light source

- Maximize productivity using Multi Optical Head

- Real time calibration technology for Scale and line-width

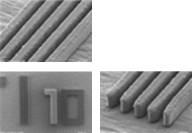

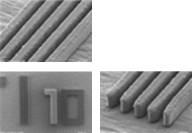

L/S=10um(DRF:25umt)

L/S=12um(DRF:25umt)

L/S=20um(DRF:25umt)

SPEC

| ITEM | SPEC | |

|---|---|---|

| Maximum imaging size | 650(W)x820(L)mm | |

| Data format | RS274X, GDSⅡ | |

| Light Source | Laser Diode | |

| Exposure Wavelength | 405nm | |

| Minimum Pattern size | 20um L/S | |

| Data Resolution | 1um | |

| Overlay | ≤±10um | |

| Throughput | 20sec (@20mj) | |

| Auto-Scaling | Yes | |

| Auto-Calibration | Yes | |

| Calibration of partial | Yes | |

| Panel Tracking | Yes | |

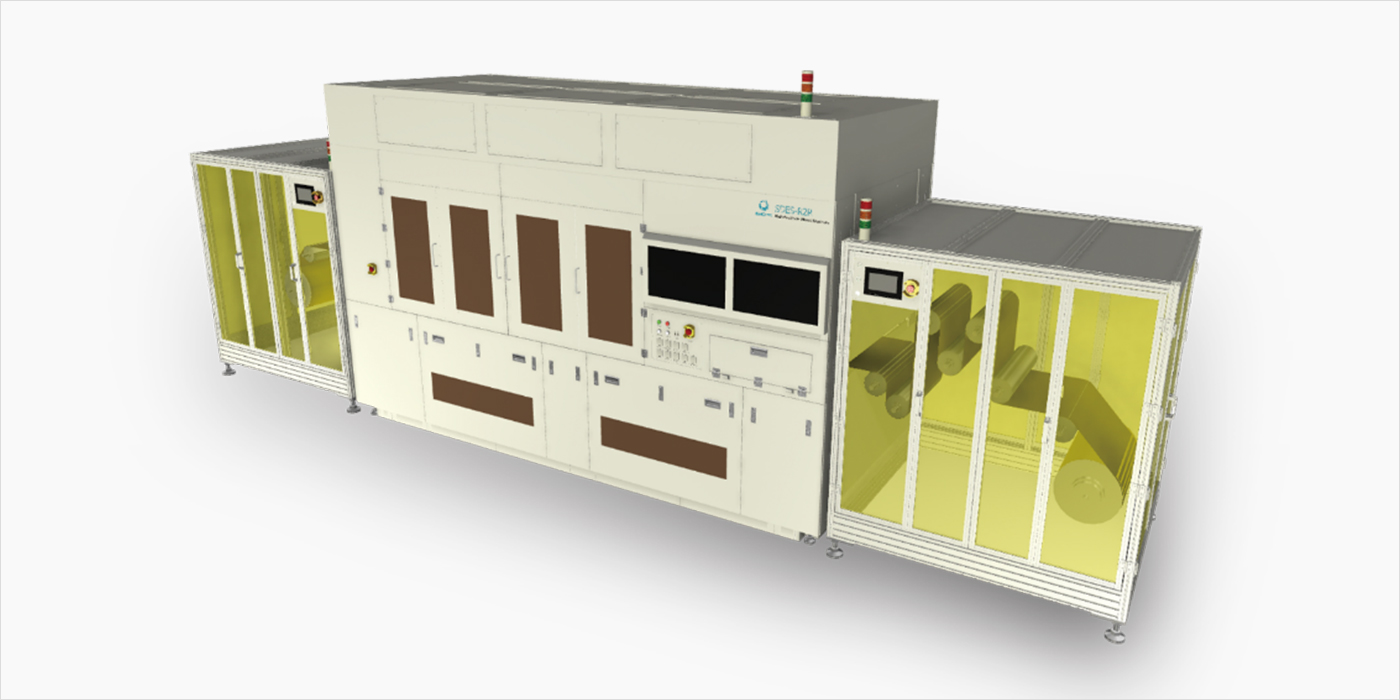

Direct Imaging System Roll to Roll

OUTLINE

- Roll to Roll Automatic equipment

- Sheet Type Manual production

- Support for smart factory system integration

- Prompt sample manufacturing lead-time

- Mass production for High density of HDI

FEATURE

- High precision double sided exposure

- High intensity laser sources

- Maximize productivity with Multi optical head.

- Real time calibration of scale and line-width

- High precision Overlay

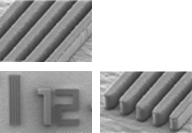

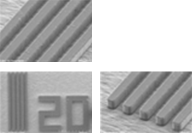

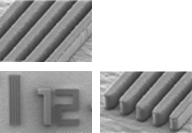

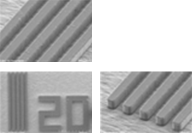

L/S=10um(DRF:25umt)

L/S=12um(DRF:25umt)

L/S=20um(DRF:25umt)

SPEC

| ITEM | SPEC | |

|---|---|---|

| Maximum imaging size | 2000(W)x520(L)mm | |

| Data format | RS274X, GDSⅡ | |

| Light Source | Laser Diode | |

| Exposure Wavelength | 375nm, 405nm | |

| Minimum Pattern size | 20um L/S | |

| Data Resolution | 1um | |

| Overlay | ≤±9um | |

| Throughput | 25sec (@23mj) | |

| Auto-Scaling | Yes | |

| Auto-Calibration | Yes | |

| Calibration of partial | Yes | |

| Panel Tracking | Yes | |

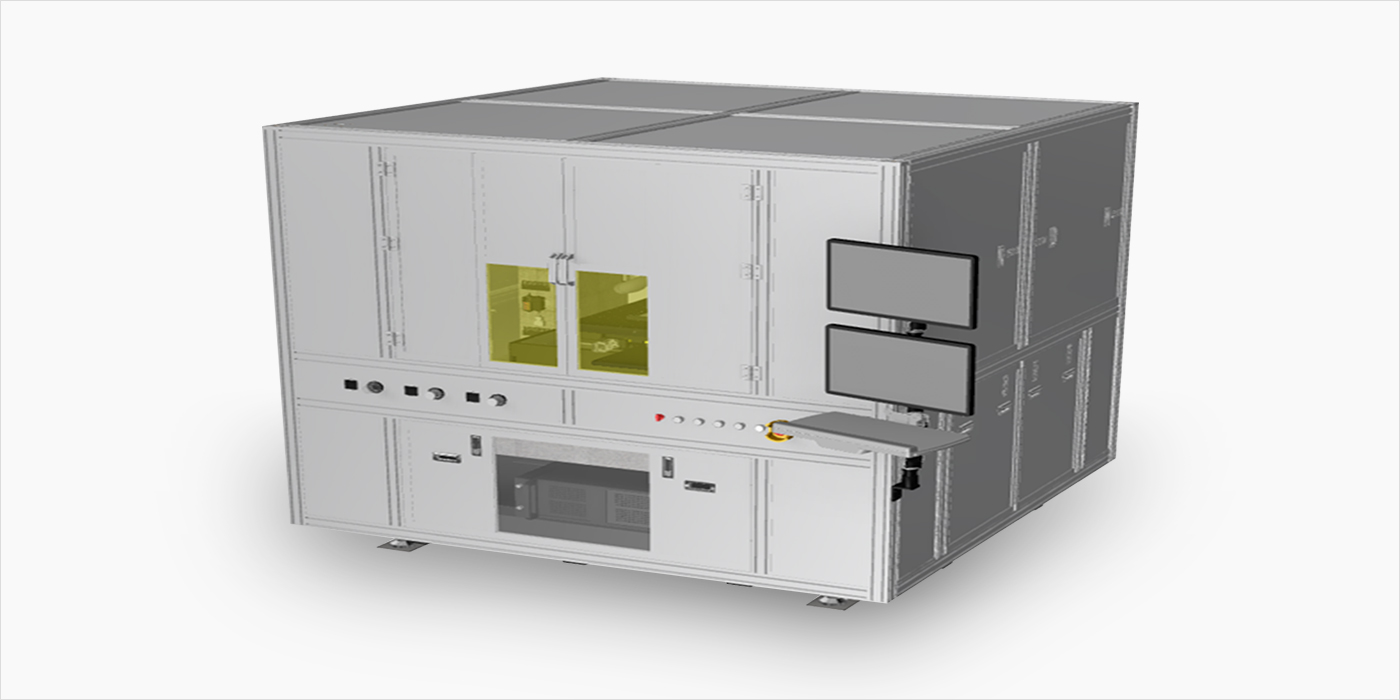

Direct Imaging System META Series

OUTLINE

- High resolution exposure system for semiconductor package field.

- Top notched L/S 5um line-width formation

- LDI Equipment optimized for Semiconductor package/Wafer MEMS 4~12”

- L/S 2/2um, 5/5um for high density and scaling-down package technology

FEATURE

- High resolution scaling-down line width

- High intensity laser (375,405nm)

- Maximize productivity using Multi Optical Head

- High precision Overlay

Independent exposure head configuration

High speed exposure

SPEC

| ITEM | SPEC | |

|---|---|---|

| Maximum imaging size | 650(W) x 900(L) mm, 2100(W) x 620 (L)mm | |

| Data format | RS274X, GDS, ODB++ | |

| Light Source | Laser Diode | |

| Exposure Wavelength | 375nm, 405nm | |

| Minimum Pattern size | 2um L/S | 5um L/S |

| Data Resolution | 0.1um | 0.25um |

| Overlay | ≤±1um | |

| Throughput | 39sec (@20mj) | |

| Auto-Scaling | Yes | |

| Auto-Calibration | Yes | |

| Calibration of partial | Yes | |

| Panel Tracking | Yes | |

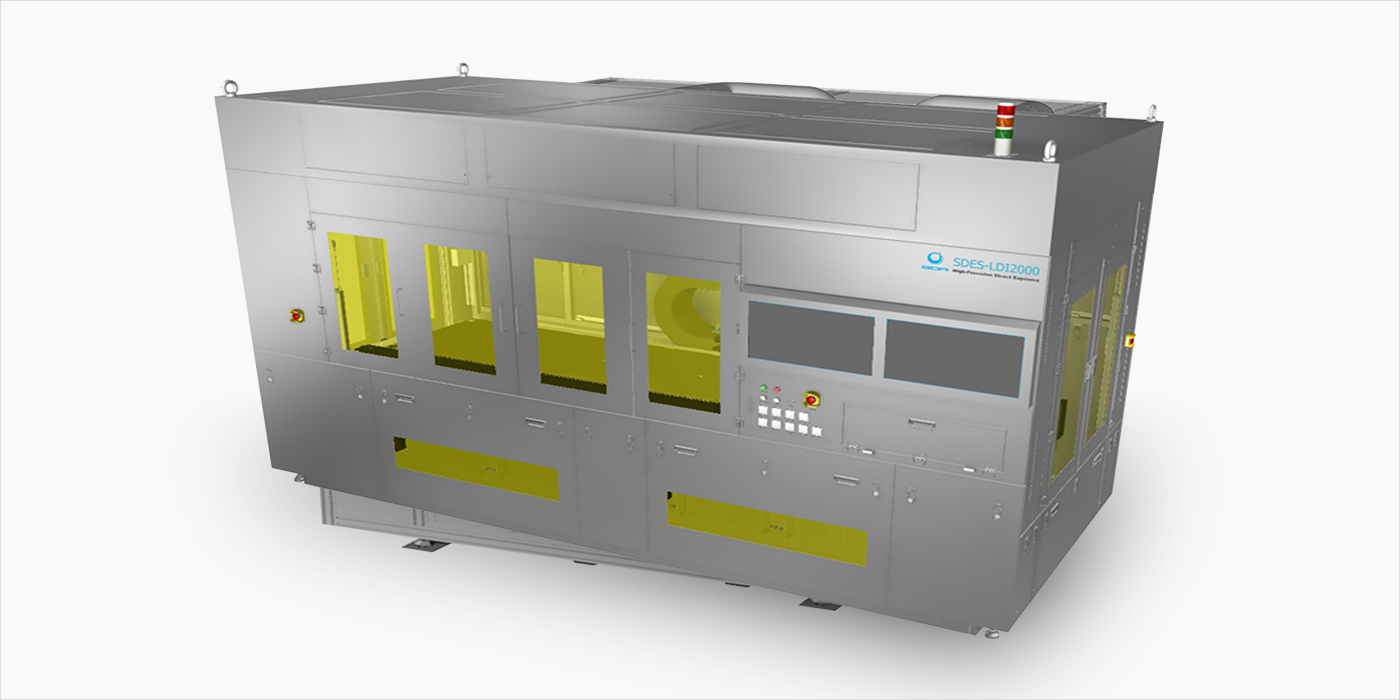

Direct Imaging System SDES-LDI2000 Series

OUTLINE

- High efficiency, High productivity L/S 10um/20um exposure engine

- 2 wave length light source (365nm, 405nm)

- Applicable to High aspect ratio substrate(Basic 600x2,000)

- Capable of arrangement at one time (Maximum 600x2,000 1EA or 300x2,000 2EA)

- Capable of Batch exposures through multi Substrate arrangement

- Capable of Multi layout alignment Scale calibration

- Divided-Calibration inside of substrate is possible

- By split exposure, Maximum 4m substrate divided exposure is possible

FEATURE

- High efficiency, High productivity exposure head

- High intensity light source (375nm, 405nm)

- Maximize productivity using Multi Optical Head

- Batch exposures through Multi Substrate arrangement

- Implementation of Divide Exposure Function

SPEC

| ITEM | SPEC | |

|---|---|---|

| Maximum panel size | 650(W)x2,050(L)mm 0.2~2mm thickness | |

| Maximum imaging size | 600(W)x2,000(L)mm | |

| Data format | Gerber data(RS274X) ODB++ (Option) | |

| Light Source | Laser Diode Module (5W, 12W, 30W) | |

| Exposure Wavelength | 405nm : 5W, 10W, 30W 375nm : 10W *Total : 40W | |

| Minimum Pattern size | 20um L/S | |

| Data Resolution | 1um | |

| Overlay | ≤±9um | |

| Tact time | < 120sec (@200mj, 175mmx2,000mm) | |

| Auto-Scaling | Yes | |

| Split Calibration | Yes | |

| Divided align | Yes | |

| Panel Tracking | Yes | |

Lithography System SDLM-Optics

OUTLINE

- Optical system for manufacturing DI(direct Imaging) Exposure equipment and data transmission module

FEATURES

- L/S(Line & Space) : 5, 10, 20um

- Light source : Laser diode 375, 405 wave length. (Singular wave length is possible)

- PCB, Wafer, Package Substrate, MEMS and Mask Writer, etc.

- Can be applicable to exposure fields.

- Development platform in Windows settings provided.

- Trigger-Based Synchronization functionality provided

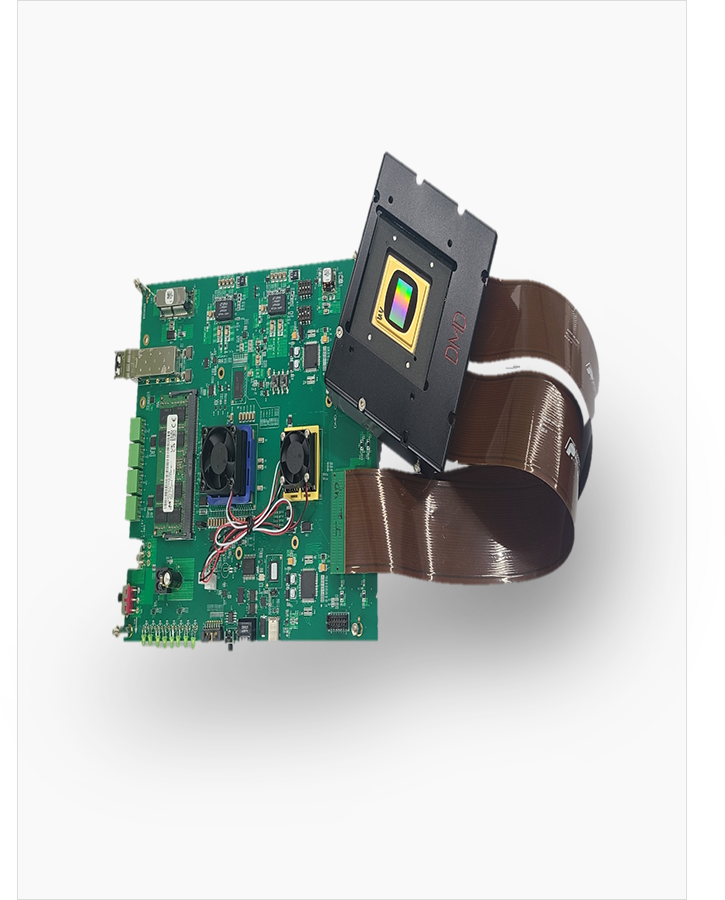

High-Performance Modules for Direct Imaging

OUTLINE

- Application in the manufacturing of DMD (TI, USA) based equipment

such as DI (Direct Imaging) machines, 3D scanners, and 3D printers. - Development platform

· OS : Windows 10 or higher version

· Tool : C#, Visual C++

· Format : SDK

SPEC

| ITEM | SPEC |

|---|---|

| Chipset | DLP9500 & DLPC410 |

| DLP Format | 0.95” 1080p |

| Window Options | VIS, UV |

| Micromirrors | 1920 x 1080 |

| Data Format | Gerber(RS274x) |

| Speed | ~22,000fps(Frame Per Second) |

| Data Resolution | 0.05~2um |

| PC Interface | 10G Ethernet |